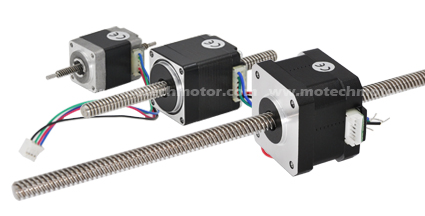

A linear stepper

motor is an electric motor that converts an electrical pulse signal into linear

motion. It converts rotational motion into linear motion through the

interaction of pulsed electromagnetic fields generated by the magnetic rotor

core and stator. Linear stepper motors can directly perform linear motion or

linear reciprocating motion without the need for external mechanical linkage

devices, thereby simplifying the design and improving motion accuracy.

To choose the

appropriate model, please pay attention to the following points:

1. Load requirements

Determine the

appropriate motor size based on the required load, such as Nema 8, 11, 14, 17,

23.

Loads are divided

into static loads and dynamic loads. Static load refers to the maximum thrust

that the screw bears when it is stationary, and dynamic load refers to the

maximum thrust that the screw bears when it is moving. When selecting, both

factors should be considered simultaneously.

2. Running speed

Select the

appropriate lead screw based on the required linear running speed of the motor,

such as Tr8 * 2, lead screw outer diameter=8mm, and lead=2mm.

The running speed of

a linear motor is closely related to the lead of the screw, which refers to the

displacement distance of the nut on the screw axis when the screw rotates one circle.

The larger the lead, the greater the displacement of the nut per turn of the

screw, and the faster the movement speed. Generally speaking, when the speed is

high, choose a large lead; When the speed is low, choose a smaller lead.

3. Movement distance

Determine the

appropriate length of the lead screw based on the required linear running

distance.

The length of a

screw includes two concepts: full length and thread length. The full length

refers to the overall length of the screw, and the thread length refers to the

total length of the threaded part.

4. Nut type

There are many types

of nuts, and when selecting, the installation size and the performance

requirements should be considered comprehensively. For example, the flange

form, length, material, and type (standard/anti-backlash nut) of the nut.

5. Usage environment and special requirements

Consider the

requirements of special applications, such as waterproof, oil-resistant, etc.

If necessary, please communicate further with our sales engineer.

In our product series,

we also offer non-captive linear motors in addition to providing external nut

linear motors.

The working

principle of the non-captive linear motor is to integrate the nut with the

motor rotor into one, and the screw shaft passes through the center of the

motor rotor. When in use, fix the screw and prevent it from rotating, when the

motor is powered on and the rotor rotates, the motor will move in a straight

line along the screw; Conversely, if the motor is fixed and the screw is prevented

from rotating, the lead screw will move in a straight line.